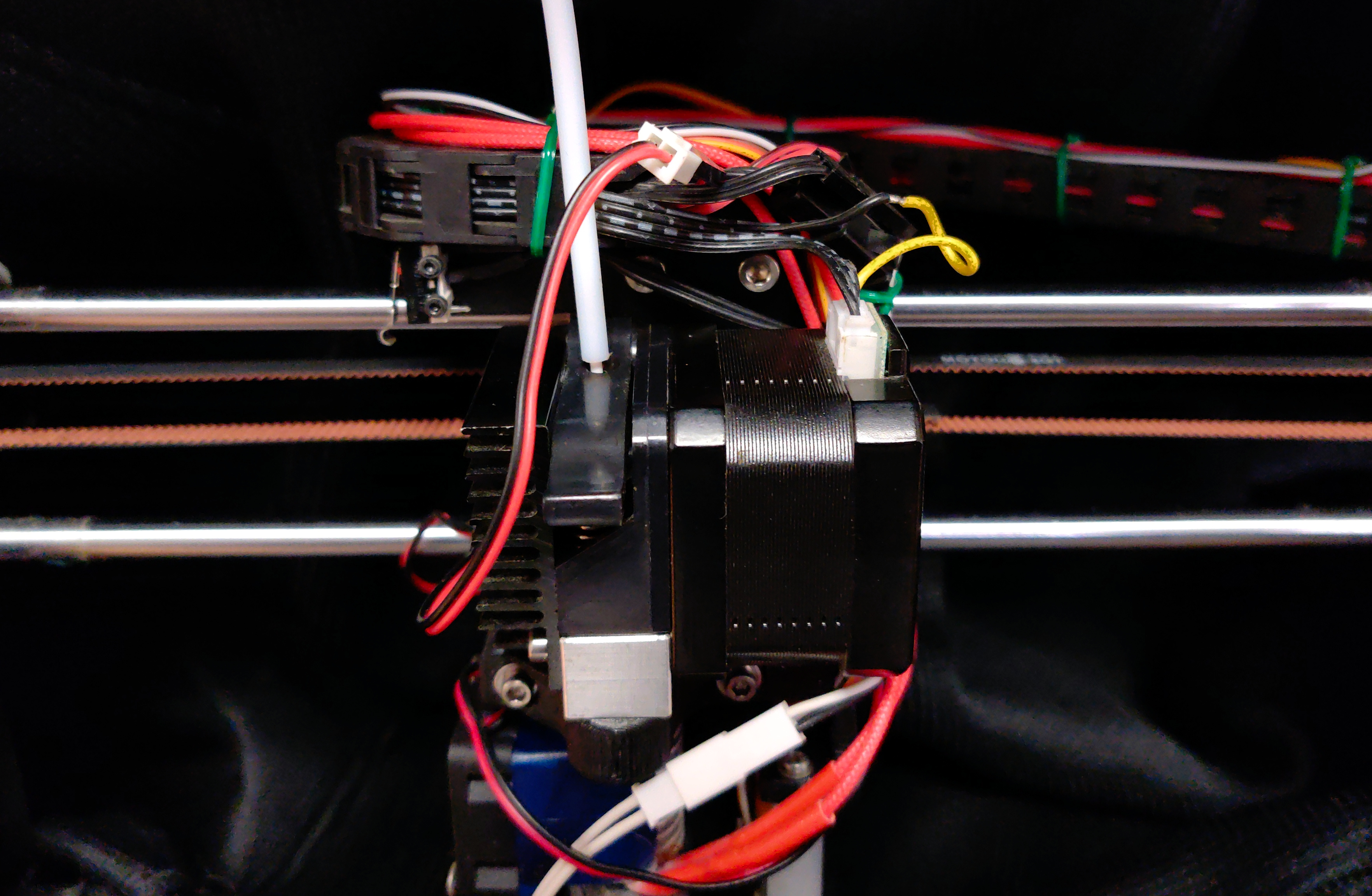

Custom Hotend Assembly

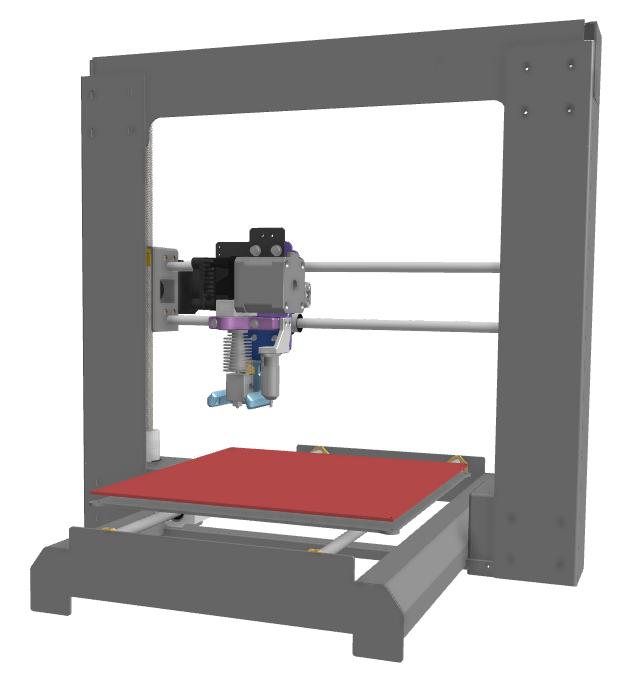

I have a Monoprice printer that I wanted to put a different hotend on. It uses a non-standard mount for the original hotend so I modelled and printed a new one to accept a standard RepRap style nozzle.

Design

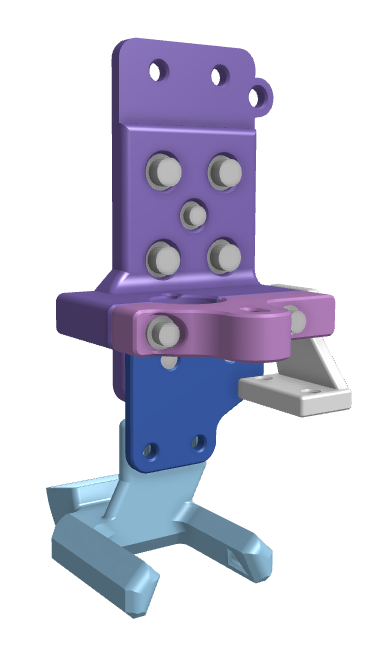

There are a few things I wanted my hotend to do

- Be able to use the existing extruder

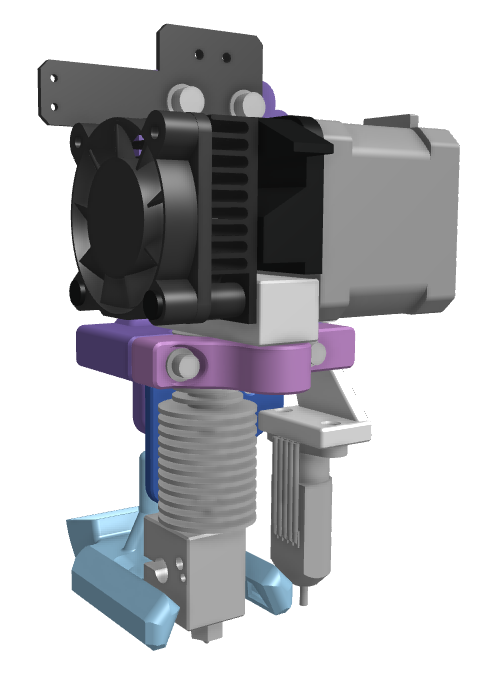

- Securely hold the E3D Volcano

- Integrate a BLTouch sensor

Modelling

I primarily use OnShape for making 3D models. It is intuitive and runs in the browser, meaning that it is agnostic of what operating system you use.

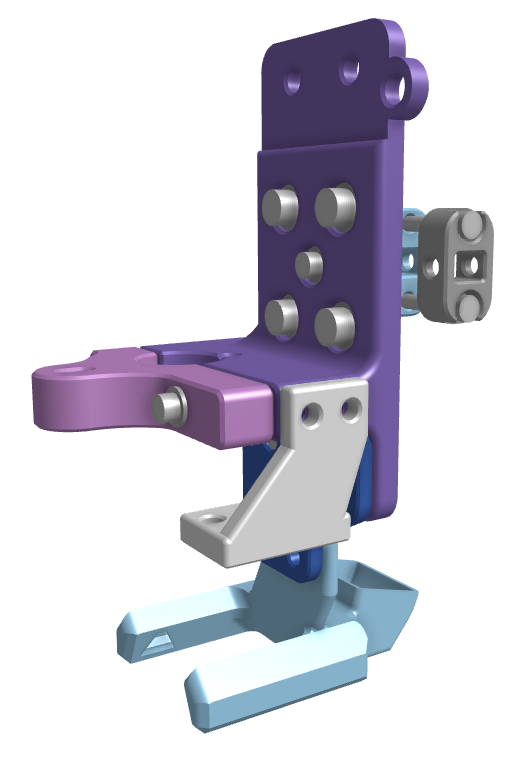

The body was relatively easy to model, the hotend is tightened in an opening between two printed parts and the extruder assembly is screwed on top. Everything fits on the printer with no modifications made to it.

I also designed a new belt tightening mechanism which worked really well. It is a big improvement over the two screws it replaced.

Simulation

I wanted to play around with CFD simulation to make sure that the flow inside the fan duct was laminar. I used a combination of openFOAM and ParaView to generate and view the data and changed the design until I was happy with it.

Firmware

The Monoprice Maker Select v1 does not have enough GPIO left on the main board to be able to control the BLTouch. I followed this tutorial to make a breakout cable for it, using the buzzer pin to drive the servo. The firmware also had to be flashed, removing SD card support and arc support to make the binary small enough to fit on the anemic microcontroller chosen for this budget printer.

End Result

I am happy with the end result, it is stiff and I have had no issues using it.